- BCM Transtech

- Corrugated Storage Solutions

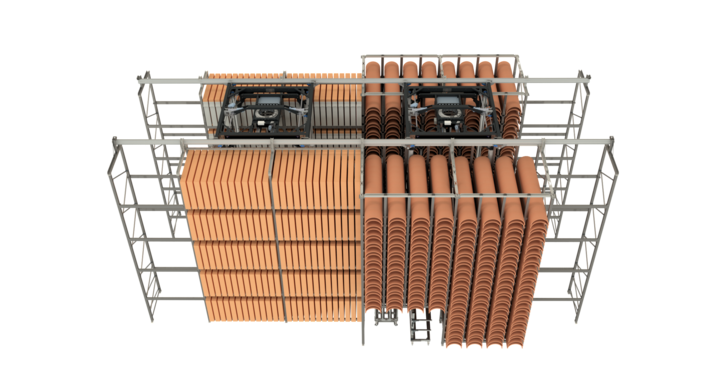

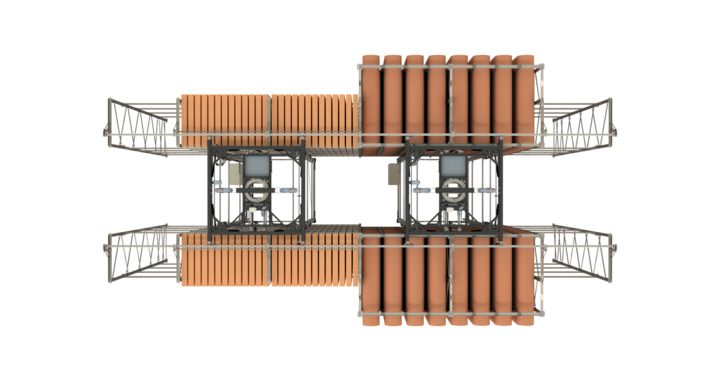

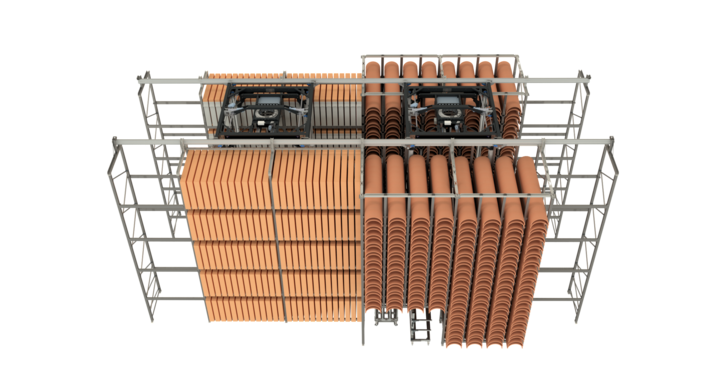

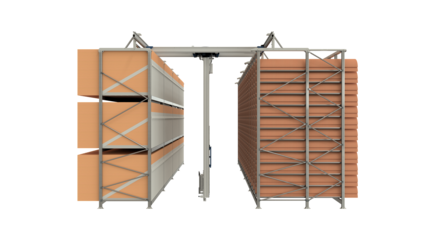

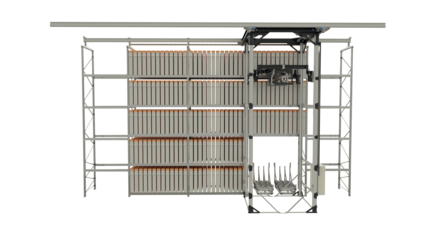

- AutoStorage FR2 T-type

FLAT BED DIE STORAGE

AutoStorage FR2, T-type

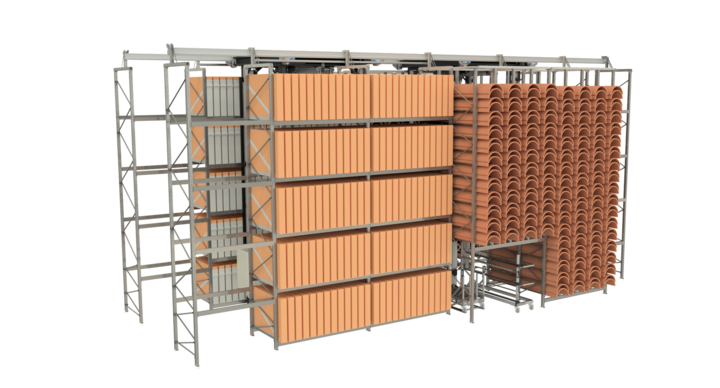

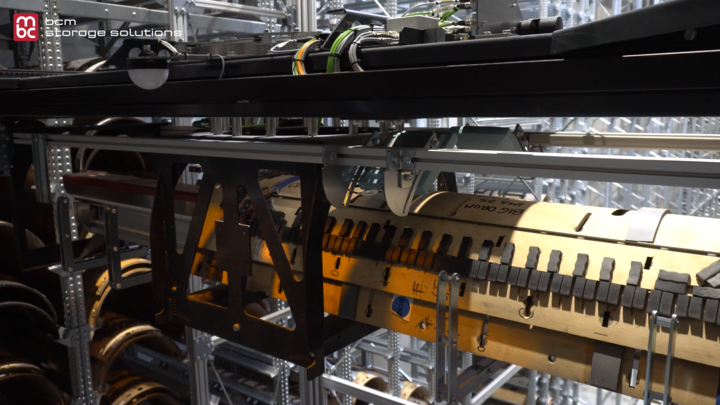

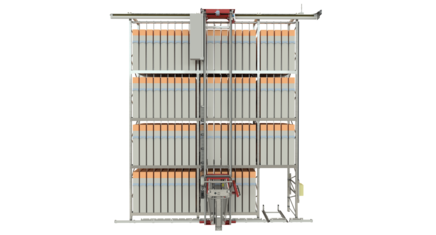

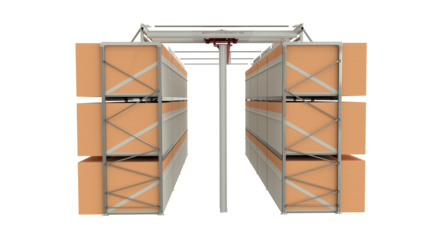

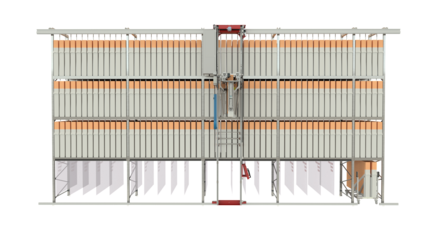

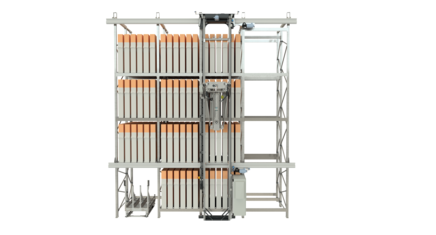

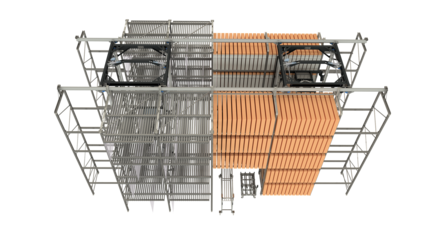

This fully automatic double rack storage solution for flat bed dies and rotary dies, with two overhead-mounted robot cranes, is useful if you have many flat bed dies and rotary dies to store. The width of the storage is determined by the size of the rotary dies, height can be up to 10 meters and length unlimited.

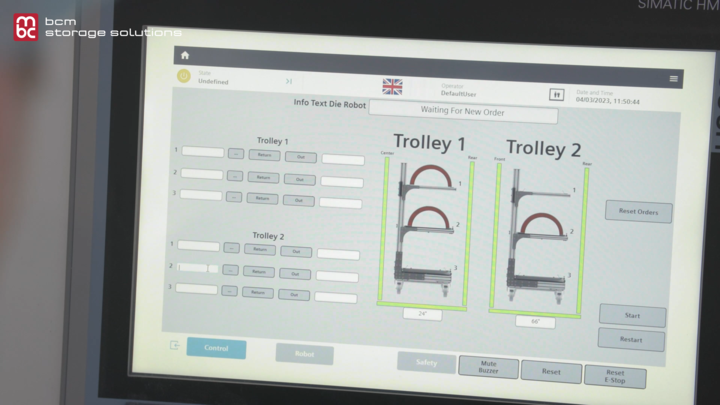

The entire storage is covered in steel sheet cladding to make a completely closed system. It is operated from a large touchscreen, and the entire system runs on a PC with database, remote access devices and more. Other software options are available for this solution, e.g., Report Module, Industry 4.0, etc.

Some of the advantages of this double rack, T-type robotic storage, compared to the single rack F-type robotic storage, are that the capacity is increased by 100%, but storage space requirements only grow by 50%, and the tools can be delivered into the trolleys in more locations, as this T-type robot crane can rotate 360 degrees.

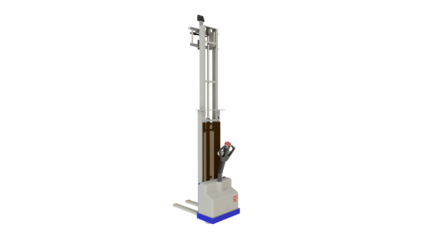

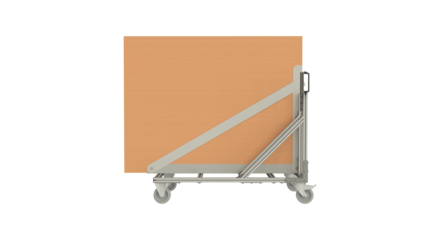

Product descriptionThe storage structure is built mainly from galvanized steel. The robot cranes and the crane rails are a combination of aluminum, galvanized steel and powder coated steel. The electronic equipment is comprised of top brands only to meet the highest quality standards available on the Western European market. The robot cranes can move in multiple directions simultaneously, making it both time saving and efficient. The operator can request multiple jobs at the same time for both storages which are then kept in the PC’s memory while the robot cranes are working through the job list. The bcm AutoStorages are simple, effective and safe, and the bcm software and safety measures ensure that it is impossible for the two robot cranes to collide in any way. This storage is two storages in one, each with their separate robot crane, and placed in extension of each other. It is obvious to position the garage area, where trolleys go in and out of the storage, in the middle of the storage. The control system is made from external suppliers’ parts and software combined with a bcm-programmed interface. bcm’s 25 years of “best practice” experience ensures that the customers get the best products available in terms of software, quality and functionality. Every bcm AutoStorage has access points for online support, including cameras on the robot crane and the storage, to monitor every movement, an advantage for both the customer and bcm.Each storage is customized to fit the space available and the needs of each customer. When the robot cranes pick flat bed dies and rotary dies inside the storage, they are delivered on a trolley in a designated garage. The trolleys and garages can have different designs and use different means of transportation to reach the converting lines, e.g., on wheels, chain conveyors, transfer carts, etc. |

Item number:5029754

- Tools 1: Flat bed dies in cassettes

- Tools 2: Rotary die

- Color: Anthracite Grey (RAL7016)

- Height: 4-10 meters

- No. of racks: double rack Flat bed dies 2-7* levels

- Software options: See "product data"

- Automation level: Full-automatic crane (Robot).

*Dependent on size and type of die

.png)